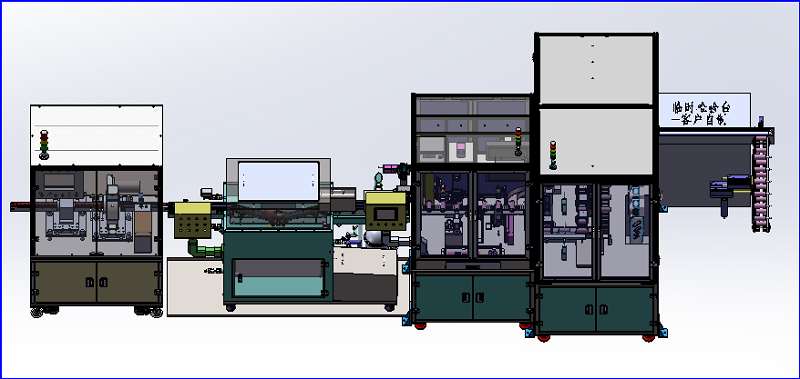

The Multifunctional Detector is a Full-automatic Detection Machine integrated large scale imported integrated circuit, multi-frequency rotating eddy current, CCD visual technology, laser measurement technology, photoelectric technology and microprocessor control, with fine designed mechanical transmission device, to form a complete mechatronics system. The software written by WINDOWS operating platform makes the use of the instrument easier and more intelligent. The instrument with stable, reliable performance, high degree of automation and fast detection speed is an on-line equipment for the detection of automobile core parts. It can establish standard detection procedures in the instrument, which is convenient for users to invoke when changing materials of different specifications. At the same time, the test data is real time saved 24 hours to ensure the traceability detection and the reexamination of 0 defects.

A、Inspection performance:

Cracks Hardness sorting Diameter testing Multi-spot testing Appearance defect Testing

【Ancillary Equipment: Demagnetization, Cleaning, Air drying, Oil coating, Laser coding, Anti-error code, Collection】

Omission rate: 0% (NG workpiece condemn OK);

Error detection rate: 3% (OK workpiece condemn NG);

B、Detection Precision:

Eddy Current: Crack L*W*T=5mm*0.1mm*0.1mm;

Image: Scratch 2mm*0.1mm, (0.1mm for depth), sand holeФ0.3mm2*Depth 0.3mm

C、Whole line inspection speed:B class --25-30pc/Min;

D、Model:

M1 Gasoline Engine: Ø12mm--30mm; Length:30-80mm;

M2 Diesel engine: Ø26mm--65mm; Length:60-130mm;

E、Equipment size: L*W*H 7500*1200*1800;