STC-P30-L Automatic packing machine (big pack) can realize the automatic bagging packaging of loose pieces of care pad.

Item NO.:

STC-P30-LOrder(MOQ):

1Payment:

FOBProduct Origin:

ChinaShipping Port:

Xiamen

STC-P30-L Automatic Nursing Pads Packaging Machine

STC-P30-L Automatic packing machine(big pack) can realize the automatic bagging packaging of loose pieces of care pad. It is composed of stacking, automatic pushing, automaticprefabricated bags loading, automatic bagging, automatic sealing, finished product discharging, automatic waste absorption and other processes to form a complete set of production processes of automatic feeding, packaging and discharging. Bags can store largerquantities.

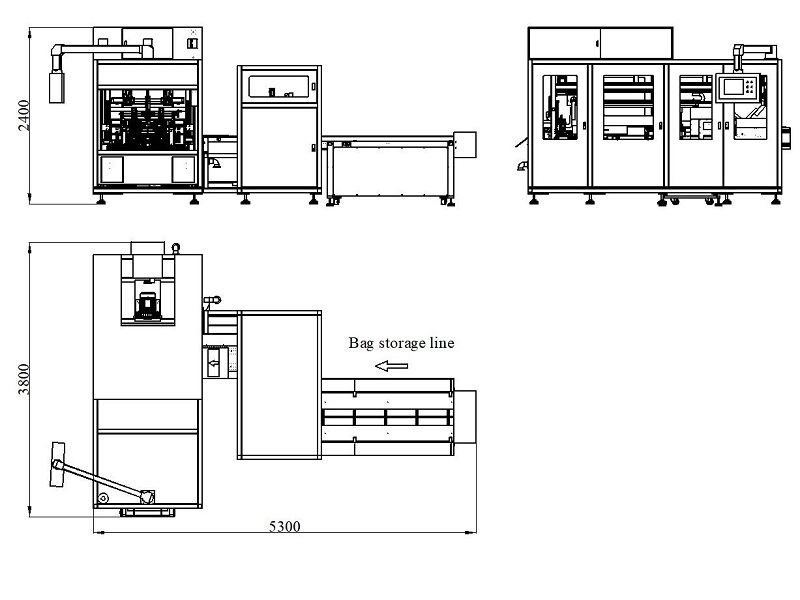

Equipment Layout:

Mechanical Structure and Technical Parameters:

Mechanical Structure:

|

Name |

Feature |

|

Material handling department |

Stable product delivery. |

|

Precompression part |

Pre-press the delivered product in preparation for pushing into the bag. |

|

Saccular department |

Open the pre-made bag in place. |

|

Bagging department |

Place theprefabricated bags over the set mold to prepare for the push part to be pushed into the bag |

|

Propulsion departmen |

Push the product into the bag in the pre-pressed position until the final seal is sealed, and the double push head is alternately carried out. |

|

Final sealing part |

Heat seal and trim the bagged product. |

|

Bag department |

Store theprefabricated bags on top to provide the bag for the upper bag section of the bag retrieval. |

|

Take the upper part of the bag |

Remove the bag from the storage area and place it on the transfer belt |

|

prefabricated bags transfer department |

Theprefabricated bags is driven by the belt adsorption and sent to the opening of the bag. |

|

Finished product discharge |

1.discharge part of each baffle to ensure the sealing molding effect; 2.Will seal good products quickly export. |

|

Final material collection department |

Automatically and collect the end material after sealing and cutting the packaging bag. |

Technical Parameters:

|

Project name |

Parameter description |

|

Equipment type |

STC-P30-L |

|

Packing design speed |

20~25 bags/minute. |

|

Packaging product:L×W×H |

vertical product size range: L:(200~450)×W:(160~300)×H:(150~220)mm |

|

Packaging material |

Double-sided heat sealing film (recommended)、OPP、Various composite heat sealing films |

|

Bag type |

Chinese bag/European bag(Handle built-in) |

|

Bag thickness |

0.05-0.1mm |

|

Main power supply |

380V/50HZ,10mm²* 5-core power cord. |

|

Installed power |

≈25kW |

|

Air pressure requirement、Air consumption |

0.5~0.6MPa;0.5M³/min |

|

Equipment size:Length×width×height: |

5300×3500×2400mm |

|

Equipment weight |

≈3600kg |

|

Sealing method |

Germany imported heating wire system sealing, cold cutter tail cutting method. |

|

Machine color |

standard: RAL9016 (traffic white). |

|

Coating raw materials |

multiple bagging stations, one station can place 50bags |