Automatic packaging machine for menstrual pants (pre-made bag) can realize automatic bagging packaging for baby pants/menstrual pants

Item NO.:

STC-D50-TOrder(MOQ):

1Payment:

FOBProduct Origin:

ChinaShipping Port:

Xiamen

STC-DC50-T Pet Pants Automatic Packaging Machine

STC-DC50-T Pet Pants Automatic Packaging Machine(rolling film) can realize the automatic bagging of pet pants loose pieces, It is composed of manual extraction from the host belt line, manual discharge, automatic bagging, automatic unwinding of package film, online bag making, automatic coding (optional), automatic punching handle hole (optional), automatic punching and exhaust hole (optional), automatic bagging, automatic sealing of the tail and self-discharging, forming a complete set of production processes of automatic feeding, packaging and discharging.

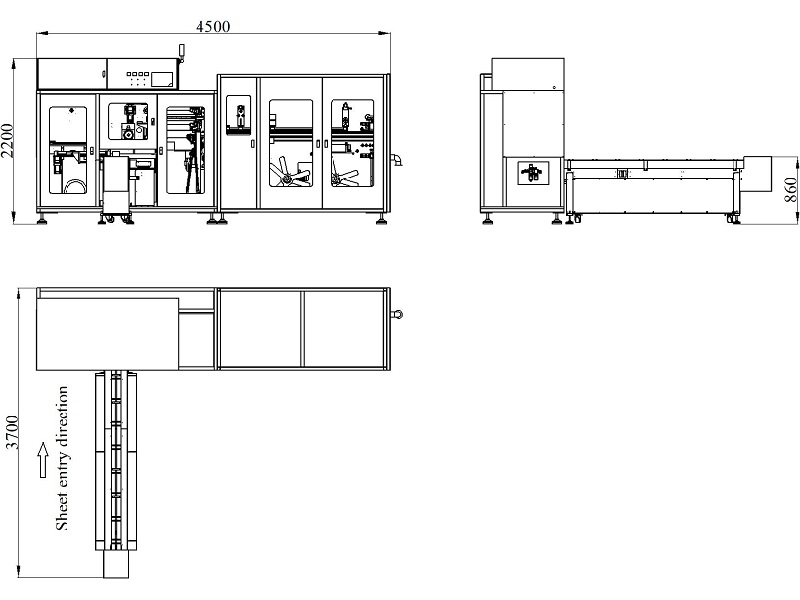

Equipment Layout:

Mechanical Structure and Technical Parameters:

Mechanical Structure:

|

Name |

Feature |

|

Material handling department |

Product stable transmission. |

|

Lifting part |

1. the product to the turntable entrance; 2.ensure that the product neatly into the bag. |

|

Propulsion department |

1.Push the compressed product into the shaped cylinder into the bag, and push it to the sealing part; 2.adjust the sealing molding of the product. |

|

Turntable part |

1.The packaging bag is delivered to the sealed entrance; 2.auxiliary products into the bag. |

|

Final sealing part |

Heat seal and trim the bagged product. |

|

Open the bag and hang the bag |

1.Transport the packaging bag to the turntable cylinder; 2.With parallel bag rolling function, to ensure the stability of the bag hanging mechanism. |

|

Finished product discharge |

1.discharge part of each baffle to ensure the sealing molding effect; 2.Will seal good products quickly export. |

|

Final delivery bag department |

Follow the color code on the roll film to ensure the position of the bag cutter. |

|

Printing mechanism |

Clamping mechanism to print the required text on the packaging bag. *Printing equipment needs to be purchased by the user |

|

Bag sealing part |

Seal the film for the first time. This feature can be blocked by the program |

|

Unwinding mechanism |

Active unwinding, can adjust the unwinding direction and speed. |

|

Punching machine or easy-to-tear wire mechanism

|

Punch holes in the packaging bag or make easy to tear, convenient for users to carry the product, or access the product. Equipment reserved tooling, punch or easy to tear device need to be purchased by themselves. |

|

Final material collection department |

Automatically collect the end material after sealing and cutting the packaging bag. |

Technical Parameters:

|

Project name |

Parameter description |

|

Equipment type |

STC-DC50-T |

|

Packing speed |

35~45bags/minute. |

|

Packaging product:L×W×H |

4~20pieces of menstrual pants L:120~200mm;200~300(Double row); W:120~240mm; H:50~110mm (can be customized)。 |

|

Packaging material |

Double-sided heat sealing film (recommended)、OPP、Various composite heat sealing films |

|

Bag type |

Chinese style bag |

|

Bag thickness |

0.05-0.1mm |

|

Main power supply |

380V/50HZ, 6mm²* 5-core power cord. |

|

Installed power |

≈13kW |

|

Air pressure requirement、Air consumption |

0.5~0.6MPa;0.5M³/min |

|

Equipment size:Length×width×height: |

4500×3200×2200mm (including front feeding line) |

|

Equipment weight |

≈2800kg |

|

Machine color |

standard: RAL9016 (traffic white). |

|

Correction system |

Unwinding using an independent correction device |

|

Bag making method |

Color label induction mode, roll film must be printed color label block |

|

Coating raw materials |

The coating is in the form of roll film, and the scroll is prepared for one use. |