Large field of vision image flash measurement, high precision, automatic, create a new concept of rapid measurement. Through the perfect combination of telecentric imaging and intelligent image processing software, any tedious measurement task becomes extremely simple.Just place the workpiece in the effective measurement area, and then gently press a key,all the two-dimensional dimensions of the workpiece will be measured instantly.Our products range from vertical, horizontal to large-size image mosaic, the most complete domestic product, independent software development, and one-stop solution!

Item NO.:

OMQ100COrder(MOQ):

1Payment:

FOBProduct Origin:

ChinaShipping Port:

XiamenOur Vision Measuring Machine can measure More Than 100 Dimensions in 1 Second

In the past, the more measuring positions, the longer measuring time, Ivt-vision can measure more than 100 dimensions at the same time. It only takes one second to complete the measurement.It can greatly shorten the measurement time.

Intuitive Interface That Anyone Can Use

Just pressing the Measure button allows the user to acquire a stable measurement result.

Measurement Results Are Automatically Recorded

Automatically saves measurement data and creates inspection reports.

Automatic Recognition of Position and Orientation

The location and orientation of the part placed on the measurement stage are automatically detected. No need for precise positioning of the part.

Automated Focus Adjustments

Equipped with a specifically designed optical lens with a large depth of field, it also automatically brings measurement points into focus. This is useful for parts with uneven surfaces, where all of the measurement areas cannot be brought into focus at the same time.

Specification & Parameters:

|

Model |

OMQ100C |

OMQ120C |

OMQ100D |

|

Measuring stroke (mm) |

82×55 |

120×80 |

82×55/20×13 |

|

Z-axis movement mode |

Automatic |

Automatic |

Automatic |

|

Optical lens |

Double telecentrc optical lens |

Double telecentrc optical lens |

Double-telecentric double-magnification optical lens |

|

Depth of field (mm) |

80 |

80 |

80 |

|

Image sensor (pixel) |

20million |

20million |

Double 20 million |

|

Measurement accuracy( μ m) |

±(2.5+L/50) |

±(2.5+L/50) |

±(2.5+L/50) |

|

±(1.5+L/50) |

|||

|

Repeatability(μ m) |

±1.5 |

±1.5 |

±1.5 |

|

±1.0 |

|||

|

Light source |

1000 level programmable light source Contour light: telecentric parallel light Surface light: LED ring light |

||

|

Image processing |

IVT advanced image analysis method, 256 gray level, 20:1 sub-pixel processing technology |

||

|

Software |

IVT-VISION |

||

|

Minimum display unit (mm) |

0.00001 |

||

|

Z-axis movement range(mm) |

45 |

||

|

Z-axis working distance (mm) |

145 |

||

|

Overall dimensions (mm) |

260×450×660 |

280×480×680 |

260×480×800 |

|

Weight (KG) |

28 |

30 |

35 |

|

Withstand load(KG) |

5 |

||

|

Work environment |

Power Supply:220V/50Hz Vibration:﹤0.002mm/s,﹤ 15Hz Temperature:22℃±5℃ Humidity:20~80% |

||

Optional:

①Special models and software functions can be customized

②Optional manual lifting work platform

③Optional surface coaxial light

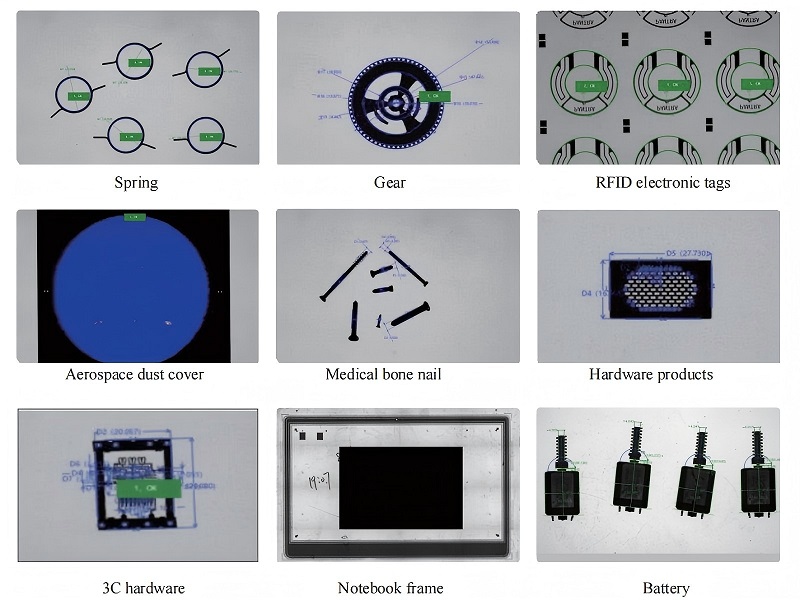

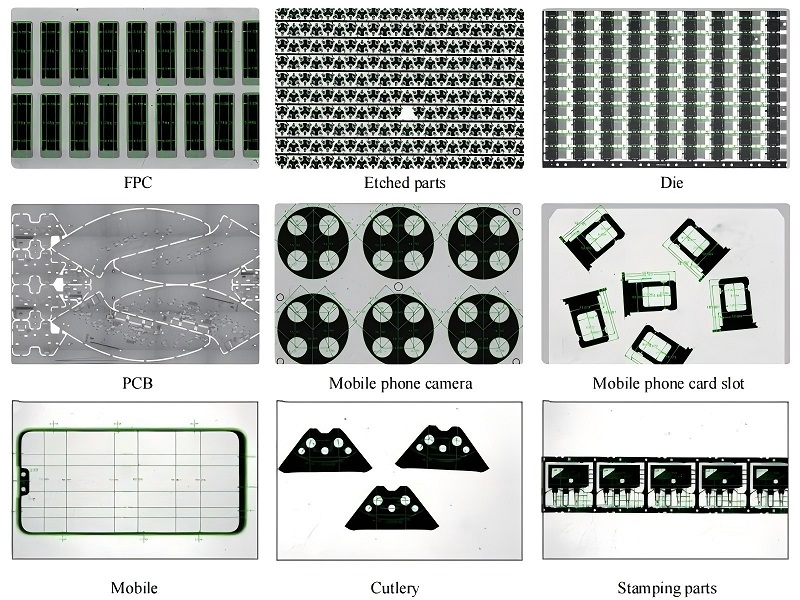

Examples of Applications: